Energy Saving Tips for your Commercial Kitchen

According to our annual customer survey, “Efficiency and Operating Costs” was the second highest concern for hospitality operators over the next 12 months, only second to “Equipment Reliability”. And with energy being one of the highest and fastest increasing costs, running an energy-efficient commercial kitchen has never been more important than now!

We thought we’d therefore look at our top tips that can help you save energy in the kitchen. From small changes you can make right now, to future investment plans which will come with longer lasting benefits to your commercial operation.

An energy-efficient kitchen is one that is built for the future, helping to increase the overall sustainability and longevity of the hospitality industry.

Take a look at our tips below and don’t hesitate to contact us if you need help with your kitchen running costs.

Changes you can make now!

In the first part of the blog, we will run through various small and easy changes you can make right now in your operation.

This includes anything from overnight cooking to optimising your lighting, heat recovery and even additional accessories which can make your catering equipment more efficient.

Optimise Your Lighting

Renewing your lighting and replacing them with LEDs is often the best place to start when it comes to saving on running costs.

Switching to LED lighting uses up to 70% less energy and lasts up to 10 times longer compared to standard incandescent bulbs. As well as using less energy, LEDs are also very good at emitting less heat into the kitchen, helping to reduce working temperatures for your staff.

LED lighting is also much more flexible when it comes to the type of light, helping make the environment seem more natural throughout the day.

It’s often worth incorporating lighting which operates on a motion (PIR) sensor, for example in areas of your kitchen that are used less frequently, like storerooms. This means that energy is only being used when someone is in there and lights won’t get left on accidentally.

Make the Most of Overnight Cooking

Overnight cooking allows you to save on energy costs because you are able to make the most of off-peak electricity.

The iVario from Rational allows you to cook overnight without needing your staff to work unsociable hours. The iVario gives you short heating times, precise temperature management, low energy consumption and quick easy cleaning. Some other benefits of overnight cooking include:

- Gain more capacity by using equipment 24/7

- Greater flexibility

- Reduction in shrinkage and greater product yield

- Safe and hygienic

As well as cooking, you can also put your combination ovens on a cleaning programme overnight, capitalising on the off-peak electricity rates.

Do you want to save energy, reduce costs and increase efficiency?

Convert Heat into Energy!

Recovering energy in your operation can reduce help your operation’s CO2 emissions and save energy consumption elsewhere!

But recovering energy from greasy, soot-covered, and polluted airstreams in commercial kitchens is difficult.

The recovered energy is used elsewhere in the building, for example in central heating, underfloor heating and hot water heating! So the money you’ve already spent creating heat can help save spending money elsewhere!

Benefit from Demand Based Ventilation

Demand Based Ventilation works by controlling the ventilation fan speed so that the exact rate is matched with the cooking demands below. This means that if no cooking is happening below, your ventilation will be running at a slower speed. Lots of cooking? A higher speed!

A fan running at 40% of its normal operating speed will only consume 6% of the energy required to run at 100% of its operating capacity. This helps create you energy savings of up to 80%!

And best of all? These systems can be retrospectively installed to nearly every extraction system!

Energy-efficient Commercial Kitchen Equipment Options

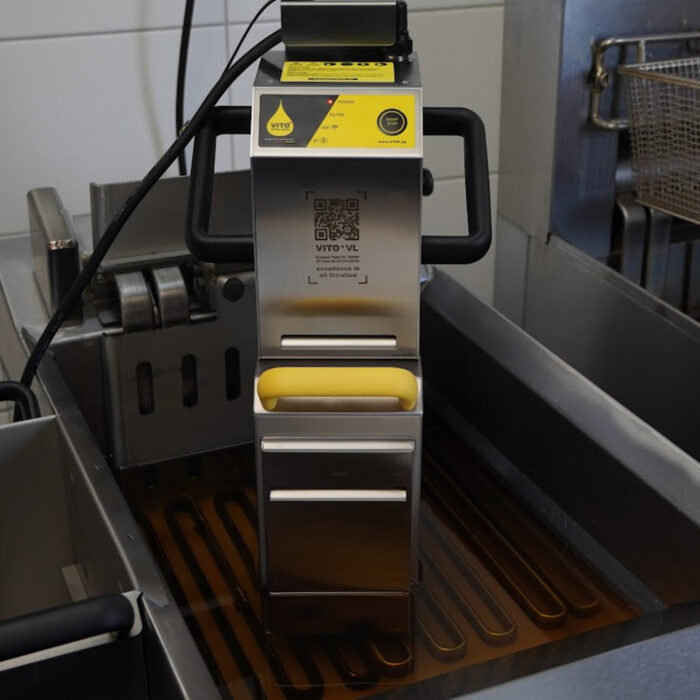

Vito VL

The Vito VL is the perfect addition to any fryer in any operation. An oil filtration system helps to lengthen the life of the oil, cleaning our dirt and debris from your fryer. Allowing you to get more out of your oil. The Vito VL can reduce oil consumption by up to 50%.

Adding Curtains to Cold Rooms

This is a cost-effective solution to save energy in cold rooms by keeping cold air in while allowing safe easy access. The heavy PVC strip curtains are suitable for temperatures from -40c to 25c.

Hot Holding

The UNOX EVEREO gives you zero regeneration, reduces your serving time, and creates you operational savings. By using this method of cooking, you loose the need to use for additional refrigeration or blast chillers. There will also be lower wastage as unopened left overs can be kept safely and served the next day.

Heat Exchangers on Dishwashers

By adding a heat exchanger onto your dishwasher allows you to cleverly combine steam reduction and heat recovery all in one. Improving your working environment and also allowing for a reduction in energy needed to heat the water.

Schedule Regular Maintenance

Keeping equipment clean and well-functioning is key to reducing costs.

Equipment that has not been cleaned or maintained properly will need to work harder and will use more energy.

A classic example …

Carrying out regular maintenance or having a Planned Preventative Maintenance (PPM) contract in place will therefore ensure that your equipment is operating correctly and performing to its maximum potential.

Using Original Equipment Manufacturer parts (OEM) that are made directly by the manufacturer will save you further repairs and replacements in the future. They are designed specifically for the equipment rather than a universal alternative.

Not only can PPM keep your equipment running efficiently, but it can also reduce breakdowns which can impact your operation, saving you money on breakdown callouts. We offer a wide range of service and maintenance contracts suitable for every operation.

Future Investments

The second part of this blog looks at future investments you can make within your operation which will not only save you energy, but will increase operation efficiency, reduce operational costs and help limit your carbon impact.

This includes monitoring your energy consumption, investing in remote refrigeration pack systems and eliminating use of fossil fuelled equipment.

Monitor Your Energy Consumption

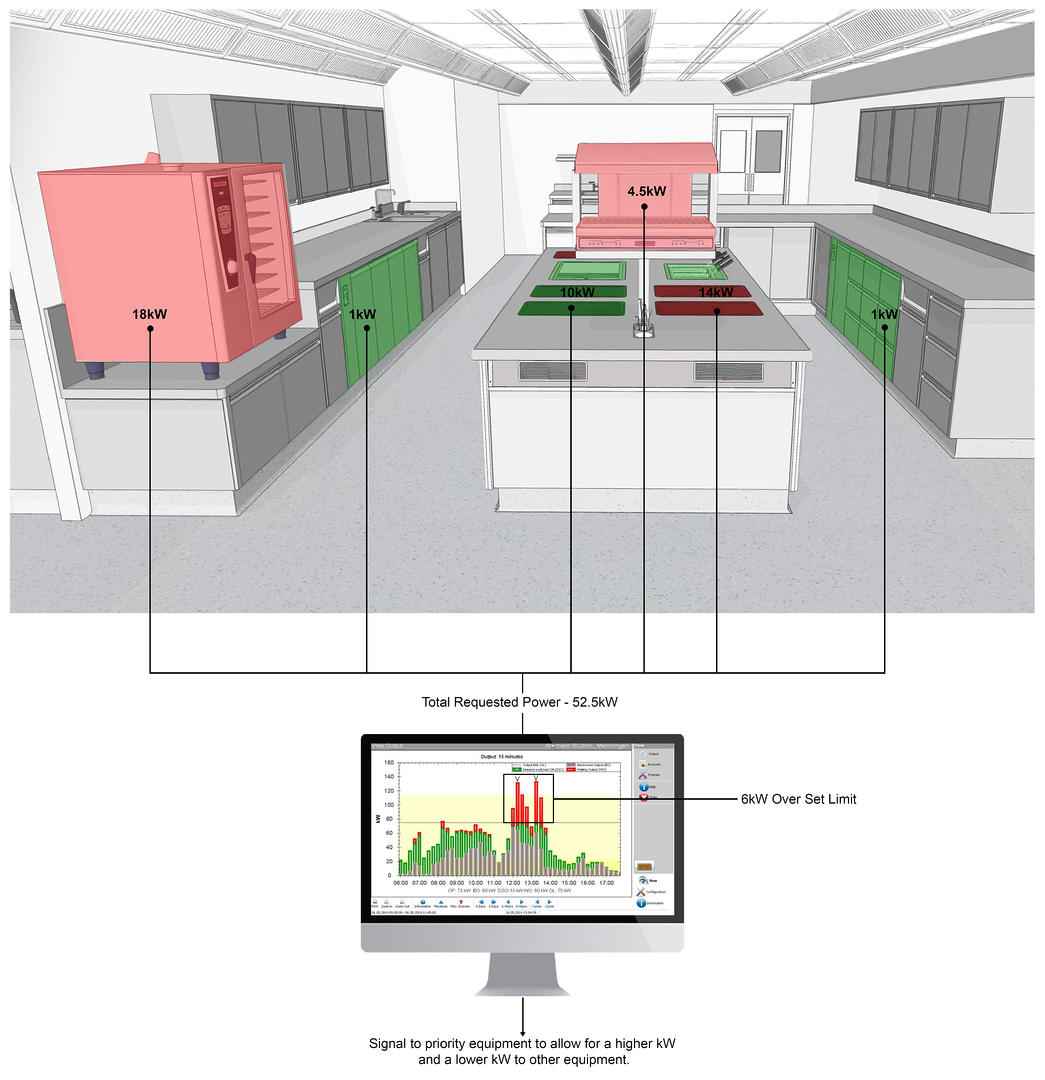

There are two principle solutions available on the market which can help reduce the connected load of your catering equipment, whilst managing your energy consumption.

The innovative solutions work by managing your kitchens electrical demand to ensure that peak power load is never exceeded. By constantly monitoring the on/off and thermostat status of each appliance’s heating, power usage, connected load and idle phases, the system is able to evaluate and optimise according to the preset parameters.

For example, equipment that requires lower usage such as pasta boiler or fryer can have its power limited, with high requirement equipment such as induction tops or a combi oven having full power.

There is also an energy management solution that can just be applied to the cook suite, giving you fingertip management from any connected device. This is an ideal solution were power supply within the building is an issue.

We have been providing energy management solutions for over 10 years, helping to reduce your energy consumption, save costs and improve the wellbeing of your kitchen brigade.

Do you want reduce your connected load within your commercial kitchen?

Remote Refrigeration Pack Systems

Did you know that remote refrigeration can provide a return on investment within 1-3 years?

While remote refrigeration pack systems can initially cost more, they are more energy efficient, can save space and heat within the kitchen, and increase refrigeration capacity or capacity for additional catering equipment.

This system is more reliable, this is because the all the refrigeration is controlled by one centralised “pack”. Within the pack, you have two compressors, meaning if one compressor is down or faulty, your refrigeration will not fail as it will still be able to run of the other compressor.

Some of the benefits of remote refrigeration in your operation include the increased lifecycle of your fridges, meaning you will not have to replace them as often, creating a huge finical savings. Other benefits include:

- Maintenance and servicing happens outside at the pack, resulting in less disruption during service.

- Removal of all heat-creating condensers located inside the kitchen.

- A cooler working environment within the kitchen, meaning your fridges and other equipment will not need to work twice as hard, helping to reduce energy consumption.

- Remote monitoring that enables staff to closely monitor energy use, and will alert them to any problems. Often these problems can be fixed remotely requiring no on-site attendance. Helping to reduce ongoing maintenance costs!

Eliminate Fossil Fuels from the Kitchen

Removing your gas equipment from your commercial kitchen is easier than you think!

Induction creates a safer, cooler and more comfortable working environment for your staff as the ambient heat in the kitchen is reduced. Reduced energy consumption is also achieved as the appliance needs no preheating and the hobs are only on when the pan is in contact with the cooking surface.

Not only induction safer, it can reduce kitchen running costs by 70% and cleaning by 90% as the equipment only needs soapy water rather than chemicals. By removing gas, you no longer have carbon monoxide and the need for costly gas interlock systems.

All-electric kitchens offer many benefits. Staff can benefit from precise control over the cooking features and functions of equipment. They can also create safer working environments whilst improving the air quality.

Need help saving in your commercial kitchen?

These are just some of our energy-saving tips for a commercial kitchen, that can help you save operating cost in the long term. Of course, there are lots of practical things you can also do such as simply as turning off appliances or not having gas burners on all day (it will be a mindset change required for your chefs!).

We have extensive experience helping hospitality venues of all sizes to reduce their energy consumption and become more efficient. Why not contact us below to find out how we can help you?