Energy Saving Kitchen

Frederick’s is a family-owned restaurant, opened in 1969 by Lou Segal, now owned by his son Nick. Situated in Islington, London, the building is Grade II listed, built-in 1767 with the associated peculiarities that had to be accounted for in any design.

The original kitchen was over 25 years old with refrigeration systems using R12 and R22 gas that had not worked properly for years; the kitchen couldn’t cope with increased covers, it was cramped, impractical and cavernous.

Services

Commercial Kitchen Design, Commercial Kitchen Installation, Energy Management

Location

Islington, London

Sector

Restaurants

Awards

The Brief

Our initial brief was to replace refrigeration, plant and pipework and design alternative ways to run pipework through the 250-year-old building. As the design progressed and we could achieve a 70% power saving, feasibility talks began to provide a totally electric kitchen, including new drains, floors, plumbing and ventilation.

This proved the most exciting part of the project, allowing us to push the boundaries of possibility and became two years of planning, design revisions and research. We visited manufacturers, looked at various design concepts and did countless electrical calculations to check the theory behind our proposals. Anything other than 100% accuracy and the power would exceed the peak connected load, and the kitchen refurbishment would fail!

The Solution

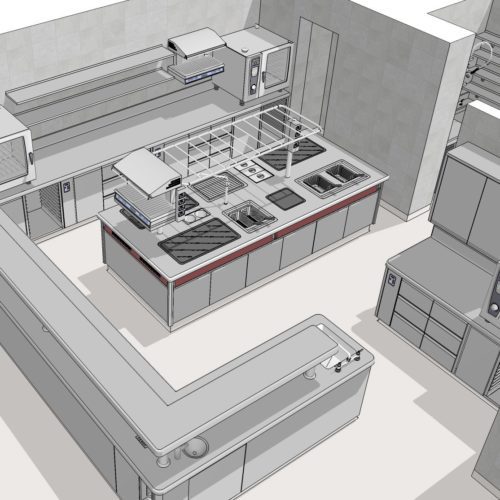

We achieved maximum hygiene by incorporating fully welded and seamless counters with solid plinths, featuring induction cooking, which is easy to clean as you go, eliminating the need for harsh chemicals.

The fully electric island induction range we installed was smaller than the original gas range. The new range is designed to improve workflow, eradicate traffic in walkways and incorporate space-saving features whilst improving the overall ergonomics. As well as this, a charcoal Big Green Egg was integrated into the range to improve the functionality of the area and expand the menu offering.

We incorporated an advanced vented ceiling and day LED lighting into the kitchen, this allowed for a better working environment for all kitchen members, as well as keeping running costs low.

The existing refrigeration compressors located in the plant room that were redundant were decommissioned and removed. Allowing this space to be used as an extra function room.

The Outcome

This was a distinct special project, it was not straightforward from the start; we had to come up with novel, innovative solutions to overcome the many problems encountered. Our design pushed the boundaries on what was achievable in the available space and met the low energy restrictions of the building. Many aspects of the project, especially all the mathematical equations needed to check the theory, were substantial and challenging and highlighted our unique approach to design and customer care.

The attention we paid to the smallest details to make sure the project ran smoothly, especially the pre-planning and design stages, allowed us to deliver a technical, high-quality project in the short time available; significantly it’s not just what you can see that makes it an exceptional project but all the non-visual aspects that will ensure the kitchen lasts 20 years or more that are just as deserving.

Finally having such great feedback and compliments from the owner (especially such a discerning and knowledgeable client) and those using the kitchen, is the real testament and justification the technology and design have given the owner exactly what he wanted.

The kitchen I have works wonderfully well, the quality is amazing. The key to a good restaurant is to retain your staff. There is no question that this new kitchen will help towards this aim. My kitchen staff are a very happy bunch.